Nonabrasive Cleaning | Softblasting | Structure Microblasting | Deburring

Swiss Instruments Limited. offers top notch iepco Microblasting Equipment and Supplies used for cleaning, deburring and finishing all types of surfaces. Contact: sales@swissinstruments.com

OVER 70 YEARS OF QUALITY & PRECISION SERVICES

MicroBlasting Equipment & Supplies

Microblasting equipments and filter systems MICROPEEN® / PEENMATIC® for production of defined surface geometries.

Questions? Fill the form to learn more.

CALL: (905) 279-1275

Superior Technology based Microblasting - IEPCO AG

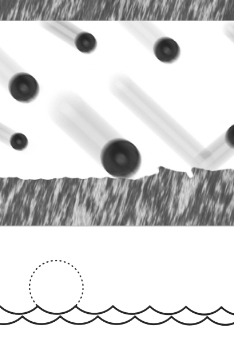

Microblasting technology is a dry, fine blasting process that uses blasting shots with defined grain sizes, hardnesses and geometries to influence the microtopography of surfaces of any kind and condition in order to change them positively.

Why do surfaces have to be microblasted ?

- 100% pure base material with no loose particles

- No preferred direction, unlike in brush finishing

- Reproducible machining process

- Time and cost savings

- Optimum adherend surface for subsequent coatings

- Repair of mould cavities to produce VDI-compliant surfaces

Ease & Accuracy - Easy to Install & Maintain

Surface Texturing | Selective Cleaning | Precision Deburring | Controlled Erosion - Service of microblasted and tribological surface treatments with IEPCOFINISH®

Industries that use Microblasting:

- Rubber, silicone and polyurethane processing

- Plastic and elastomer form tools

- Punching, compression and cut-off tools

- Extrusion die and aluminium die casting

- Propulsion technology and engine construction

- Electronic and chemical industry

- Mechanical engineering parts for textile processing

- Watch and jewellery industry

- Medical technology

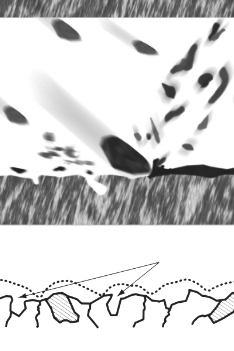

IEPCO Microblasting in 2 Steps

The technology presented below is to be applied for eroded surfaces, ground surfaces and HSC milled cavities and mould sections.

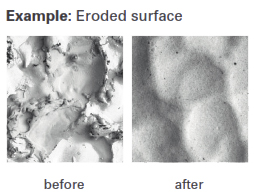

Eroded surface

The so called “white zone” adheres to the thermally damaged surface and can lead to problems in subsequent coating ( PVD, CVD and galvanic ). Thermal post-treatment is also negatively influenced.

Step 1: Cleaning

The surface is cleaned and uniformed with a fine, pointed microblasting shot that also removes all loose parts. The adherend surface prepared for all types of coating, if necessary.

Step 2: Densification

The mould surface is densificated while tribological additives are simultaneously dispersed into the metal surface. The tribological properties are improved for a wide variety of applications.

High Quality, Precision & Controlled Erosion

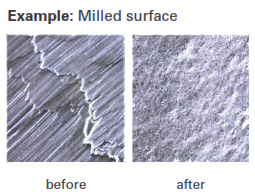

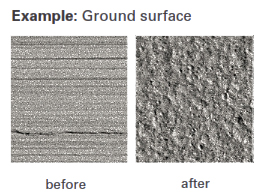

Furrowing, overheating and grinding wheel residues from grinding, steps from milling, splintering or base material stripping from HSC milling. These sometimes undesired appearances after machining can be eliminated with iepco microblasting.

Blasting Shots | Microblasting Media

Our IPECONORM abrasive media cover almost every area of application in the field of microblasting technology.

We can offer the following media:

- Special fused alumina

- Ceramic abrasives

- Silicates

- Rustfree abrasive media

- Hardened glass balls

- Plastic blasting abrasives

- Organic abrasive media for sensitive mould cavities

- Abrasive media with tribological additives on the surface of the blasting shots

We also supply the application technology to go with our microblasting media and can mix or screen the abrasive media to suit your particular application.

Don’t hesitate to ask us!

Advantages of IEPCO Microblasting over conventional cleaning methods

- No thermal damage to the components and moulds

- Time savings

- No solvents required

- Reproducible cleanness

- Environmentally friendly